Scroll Down

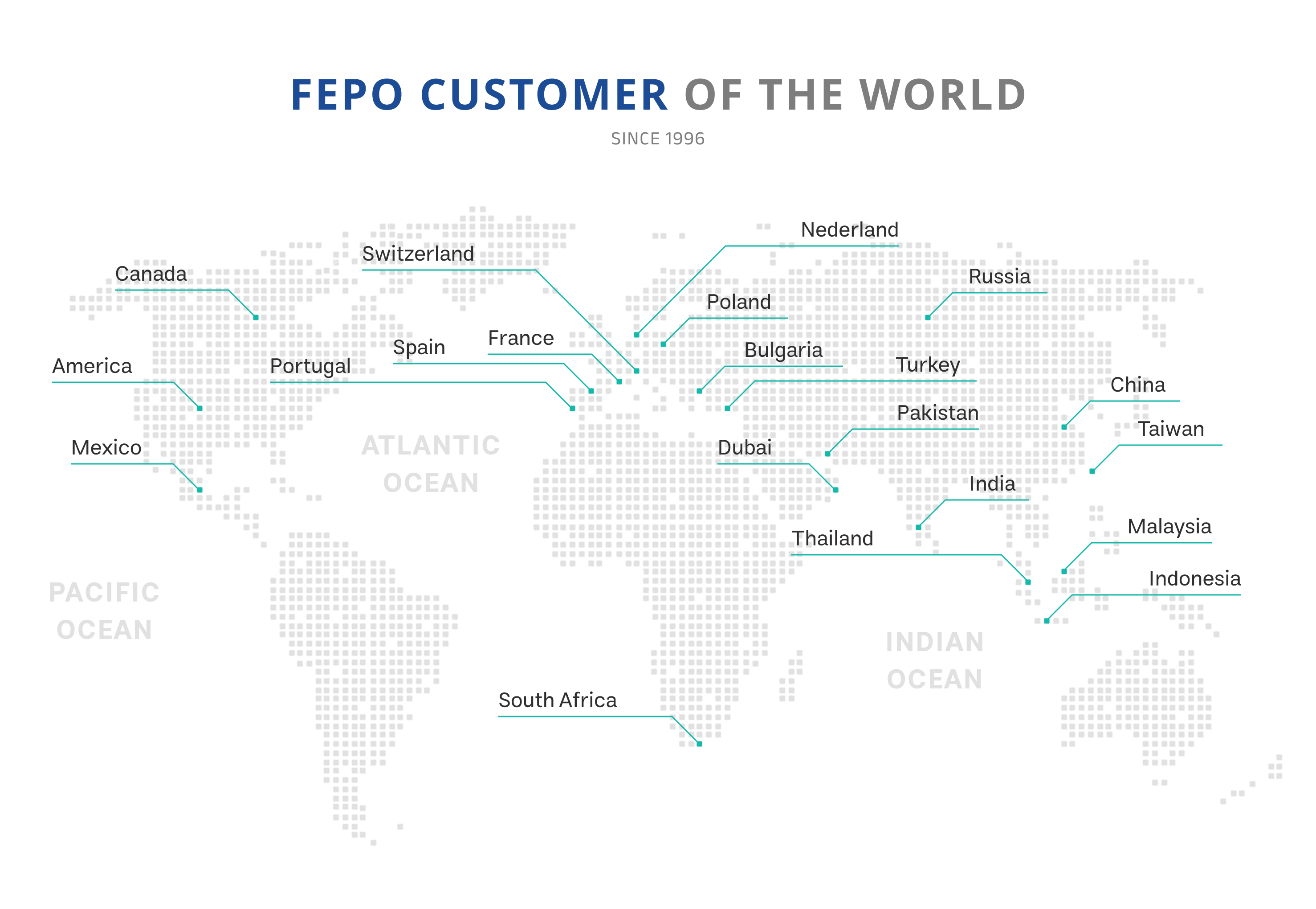

Founded in 1996, FEPO Industrial Co., Ltd. has spent nearly three decades specializing in spindle and tailstock solutions for machine tools, proudly serving customers worldwide. Driven by a commitment to “innovation, quality, efficiency, and sustainability”, we continuously refine our processes to deliver superior performance and stay competitive on the global stage.

FEPO specializes in customized precision engineering with strict quality control in a climate-controlled environment. We continuously advance our technology and processes to deliver high-quality solutions for the global precision machine tool industry.

Establishment

Global Customers

Accuracy

Number of custom cases

FEPO develops large-scale lathe spindles and dressing systems with integrated bearing technology for lasting precision and performance. We innovate to deliver reliable solutions for the precision machining industry.

FEPOTEC Upgrades Its In-House Mitsui Vertical Machining Center The Mitsui vertical machining center at FEPOTEC has undergone a complete upgrade, including the replacement of its controller and servo system. This modernization ensures the continued capability for development and mass production, maintaining the highest quality standards for our customers.

The spindle of the 618/614 surface grinder is the core component of small precision surface grinding machines, widely used in mold processing, tool reconditioning, and precision parts grinding. Its design emphasizes high speed, high precision, and high rigidity, ensuring stable and superior machining quality even under fine-feed conditions.